Redesigning a Biotech Workhorse

From startup origins to scalable production.

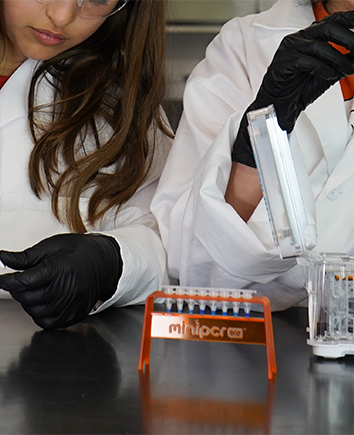

10-year evolution of the miniPCR thermal cycler.

The Original

Originally designed on a startup budget, the first miniPCR devices were built to meet immediate needs with low-volume production constraints. As demand grew, the limitations of the early design became clear.

Design Goals

-

Prepare the product for high-volume manufacturing

-

Improve strength and assembly efficiency

-

Update styling while maintaining brand familiarity

Exploration & Concepts

Explored form and construction options that preserved key visual cues from the original, while enabling better manufacturability and impact resistance.

Final redesign optimized for injection molding and snap-fit assembly. Impact resistance and internal structure were improved, while visual updates kept the product recognizable to long-time users.

-

Well-received by end users, with styling that aligned with their expectations and preferences.

-

Cut assembly time by 75% through an intuitive design that also reduced training needs and assembly errors.

-

Improved structural integrity for enhanced durability and long-term performance.

Same function, evolved form. Designed to scale.

-

Well-received by end users, with styling that aligned with their expectations and preferences.

-

Cut assembly time by 75% through an intuitive design that also reduced training needs and assembly errors.

-

Improved structural integrity for enhanced durability and long-term performance.