Stanley Tools: Redefining Jobsite Organization

A user-driven solution that shaped a lasting design legacy

Overview

As part of the Industrial Design team at Stanley Tools, I developed a new professional tool organization solution based on user workflows. Through deep research and iterative design, we delivered products tailored to how tools are used in real construction settings—and introduced a category-based product strategy that continues to evolve today.

Deep Research & Field Interviews

We began by visiting jobsites and interviewing professionals across the construction spectrum. This revealed a key insight: tool usage follows a four-stage workflow on site.

-

Foundation

-

Framing

-

Installation

-

Finishing

Defining Product Categories

We restructured our approach around three tool categories tied to construction phases, instead of tool type alone.

Stages 1 and 2 involve large, heavy-duty power tools and basic hand tools. These phases typically require larger crews, increasing the likelihood of tool loss or theft.

Current tool storage: Project box, wheeled chests, toolboxes and belts

Desired features: large chests and bulky toolboxes, with strong security features as a major advantage.

Stage 3 involves the greatest variety of tools and trades. This includes large electric saws, handheld power tools, and a wide range of hand tools, depending on the task. Multiple crews often work simultaneously, and tool loss or theft is common on larger job sites.

Current tool storage: Project box, wheeled chests, toolboxes and belts

Desired features: a tool storage system that accommodates hand tools, small power tools, and organizers for small parts.

By Stage 4, the house is largely complete, with most remaining work focused on installation. The tools used at this stage are typically small, sharp, and delicate. Protecting finished surfaces becomes just as important as completing the tasks themselves.

Current tool storage: Project box, wheeled chests, toolboxes and belts

Desired features: customizable tool storage that is easy to transport around the worksite.

From User Needs to a Modular Concept

Our research across three professional categories, Framing, Installation, and Finishing, revealed distinct tool storage needs. These insights guided us toward a new direction: a modular tool organization concept that could flex to user workflows and evolve with the jobsite.

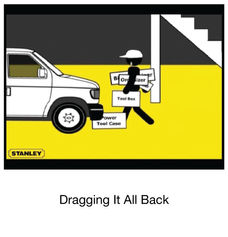

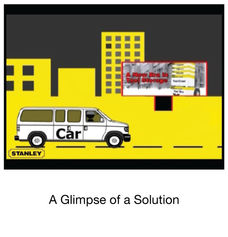

To communicate this vision, I created an animation that highlights the core challenges professionals face on site, and introduces a concept for modular, stackable, and task-specific tool storage.

The Finishing Toolbox as a Pilot

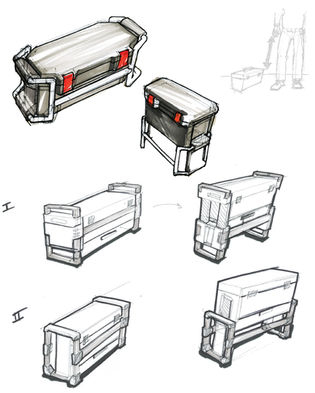

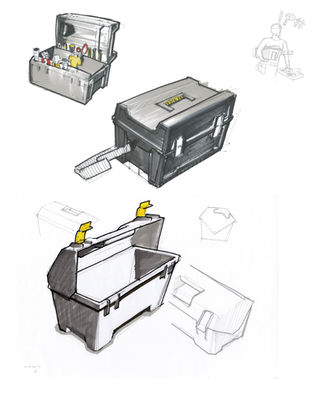

As a first step toward this modular system, I focused on developing the Finishing Toolbox, a lightweight, highly portable solution tailored to trim work and final-stage details.

While the product itself was not finalized during my time on the project, I led the exploration of:

-

Form factor and carry ergonomics

-

Transparent lids and one-handed latches

-

Stackability and modular tray inserts

These early explorations laid the groundwork for the visual and functional language that would shape the larger product family.

The Finishing Toolbox as a Pilot

As a first step toward this modular system, I focused on developing the Finishing Toolbox, a lightweight, highly portable solution tailored to trim work and final-stage details.

While the product itself was not finalized during my time on the project, I led the exploration of:

-

Easy to carry while moving around the jobsite

-

Displays tools clearly for fast, easy access

-

Customizable compartments to organize and protect precision tools

-

Clean but rugged geometry

These early explorations laid the groundwork for the visual and functional language that would shape the larger product family.

Setting the Design DNA

The Finishing Toolbox became a testbed for establishing a design language that reflected real-world needs: balancing durability, mobility, customization, and user efficiency. Rather than styling for aesthetics alone, we focused on function-driven design aligned with construction workflows.

Core principles that shaped the design language:

-

Designed with the construction stage and environment in mind, what tools are needed and when.

-

Mobility in and out of the work area, as well as during the task itself.

-

Modularity and customization to suit different trades and toolsets.

-

Easy accessibility, tools should be visible, reachable, and organized.

-

Ergonomics for lifting, carrying, and working around the box

These design pillars were later adopted across multiple categories and scaled to rolling storage, drawer units, and wall-mounted systems.

Influence Beyond a Single Toolbox

Although I did not complete the final manufactured version of the toolbox, the design strategy, language, and feature set developed in this project shaped an entire line of tool organization products at Stanley.

This category-based approach and modular vision informed dozens of products released over the next 17 years. From mobile jobsite boxes to stackable organizers, the principles we established remained central to Stanley’s storage design philosophy.